As any artist will know, ideas for a design can come from anywhere, at any time; a discussion with a friend, something seen on TV, or a new tool that could give a new texture or affect, for example. This is what happened to woodworking enthusiast, Youssef Benzaoui....

Youssef was already familiar with Computer-Aided Design (CAD) from working in industrial maintenance, but loved working with wood in his spare time. He comments, "One day I was browsing the back of a CAD magazine and there it was, "turn CAD drawings into carvings on wood and other soft materials with a CNC router." I took the plunge and bought a CNC router, a CADCAM package and started a small business making signs, engraved wood panels and other items.' Two years later, he closed his business to join a high-end woodworking company in Seattle as a CNC programmer.

Youssef has now been programming and operating CNC machining centres for fourteen years, but continues to create pieces from home with his 4' x 4' gantry router made by Digital Tools. He explains,

I already had old versions of Enroute and BobCAD as they came as part of a machine package but when I found out about ArtCAM at a woodworking show I was hooked! The local reseller gave me a sample file of a lizard to try and I machined it in a piece of high density foam. I still have it!

Youssef uses Delcam's entry-level CADCAM software package, ArtCAM Express to carve and engrave wood. One of his first projects was a bamboo magazine holder; inspired by old circular word patterns used in stone mosaic floors. He comments:

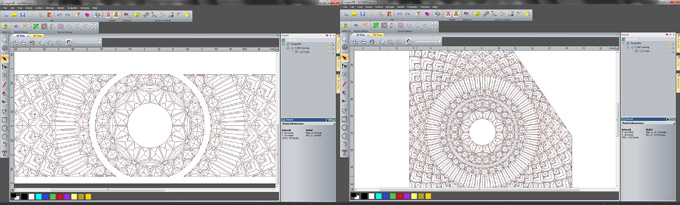

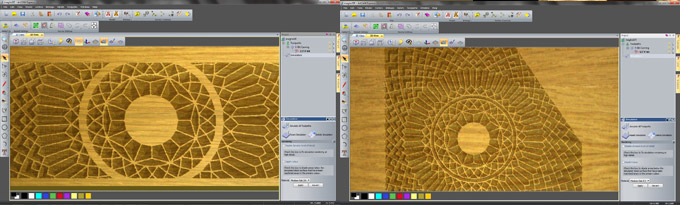

The design geometry was created in AutoCAD before I bought ArtCAM Express but after purchasing ArtCAM, the idea came to adapt it to the magazine holder on all faces, and carving it with a 90 deg V-bit using the 'V-Bit Carving' toolpath. I then imported the AutoCAD file into ArtCAM Express and used the 'Vector Doctor' tool to pinpoint any failed geometry, where arcs and segments didn't "fillet" properly in the original drawing.

To make sure that he was happy with the design before machining, Youssef used the '3D Graphics Options' in Express to render the design in a range of materials. He then simulated the selected toolpaths to make sure that there were no loops or broken toolpaths, which would cause machining issues. In Youssef's words, "I used ArtCAM for things I couldn't do in AutoCAD: the CAM part, the rendering and the simulation." Once satisfied, he then selected the CNC Shark Pro (Inch) (*.tap) post-processor compatible with his router from the database of approximately 350 processors already included in the software.

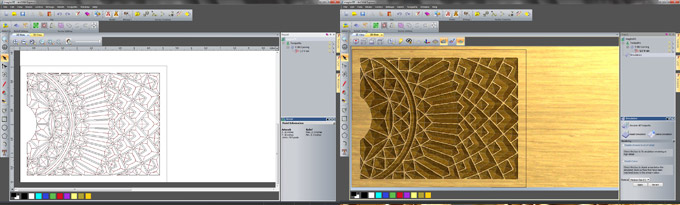

Despite being one of many to enter into Delcam's ArtCAM Express design competition, Youssef's geometric design won him one of ten Express Modules, which allow users to tailor their software with additional design and manufacturing functionality. Youssef chose the 'Texture Toolpath' module 'because of its dual use'. He explains:

First, it can create a background for a design (e.g. a sign) and second, it's a great pattern maker for large panels - your imagination and the size of the panel are the limit. I want to work on 4' x 8' MDF panels and try some patterns and designs I have in mind.

Youssef concludes:

If anyone is considering buying ArtCAM Express, I think that they should go for it! It's a good starter package, decent price and you can expand when your needs grow by adding modules.