Joe Valasek, owner of Woodscape Designs, is a signmaker and sculptor with 25 years experience. Examples of his intricate work can be seen to the right. Until 4 years ago much of Joe's work involved a great deal of hand carving with chisels, routers and rotary tools.

Joe's continuing frustration with the fact that traditional tools would only allow him to carve one piece at a time caused him to investigate the possibility of utilising some kind of CAD Software.

In the middle of a carved mural I realized that I should be able to develop a method of reproducing them so that I could make the prices viable for a larger market.

After looking at the master stylus type of carving reproduction machines, Joe decided to pursue getting a CNC Router. Then, he began his search for the software that would help him build his intricate designs. Joe considered a number of options, but after seeing a presentation in the States demonstrating ArtCAM's capabilities, he chose the solution from Delcam.

My experience is that ArtCAM is an incredibly capable and easy to use application. It provides the tools and flexibility I need to produce extremely detailed work in a timely manner, and leaves room to experiment with new ideas. There's nothing better on the market.

Joe made excellent use of Delcam's training. He was up and running in a short period of time and applying many of the software's features to his detailed designs. Now, he uses the program for his work nearly every day.

ArtCAM is an essential ingredient in all the work I do nowadays. I couldn't be doing what I'm doing without it.

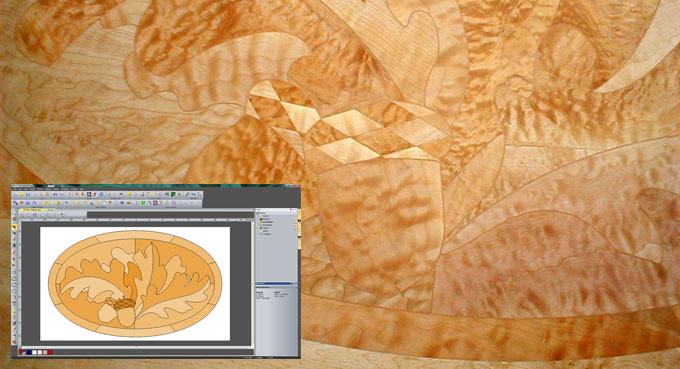

The Inlayed Floor

Joe created the design of Oak leaves and acorns in an oval using the drawing tools in ArtCAM. When the design was complete it became necessary to have each shape be a closed vector like pieces in a jigsaw puzzle. At this point the shapes were then nested and cut out using the Straight page under Male Inlay or 2D Profiling. Joe used a zero tolerance to get a very tight fit.

The wood used was Birdseye Maple which being quite hard needed 3 passes using a ¼" straight bit to cut the ¼" wood.

I found it best to simulate the shapes of the wood pieces in Artcam and add the knots so the inlay shapes could be fitted around them.

The pieces were screwed to a spoilboard and routed through.